Laser Cutting In Melbourne

Over 55 years strong, Wigley Engineering is a trusted name for laser cutting in Melbourne.

Whether you need to laser cut steel, aluminium or alloys, our skilled specialists will see it through. We offer unrivalled value and efficiency for projects in a variety of industries, from engineering and construction to manufacturing & shop fitting. By trading heavy machinery for state-of-the-art lasers, your business can minimise material waste, accelerate production & ultimately cut costs.

Laser Cutting For Metals & More

Do you need laser-cut signage, building materials or more for your next project? Our Laser Cuttng is suitable for a range of applications, our CO2 Prima Platino and Bystronic ByStar Fibre lasers cut the toughest materials with unparalleled precision.

- Mild Steel

- Stainless Steel

- Spring Steel

- Galvanised Steel

- Aluminium

- Zinc

- Copper

- Brass

Why Wigley Engineering?

Laser Cutting Since 1966

Efficient Service At Any Scale

Premium Quality, Every Time

Start-To-Finish Customer Support

Local Laser Cutting In Melbourne

Make Your Mark With Custom Laser Cutting

Create even the most complex custom designs with exceptional accuracy and consistency. As a leading provider of sheet metal laser cutting in Melbourne, we can slice exact specifications to meet your unique needs. Working with your business throughout the entire process, our experts will ensure an impeccable outcome down to the millimetre. We also offer cost-effective prototyping, giving you the opportunity to refine results as required.

Frequently Asked Questions

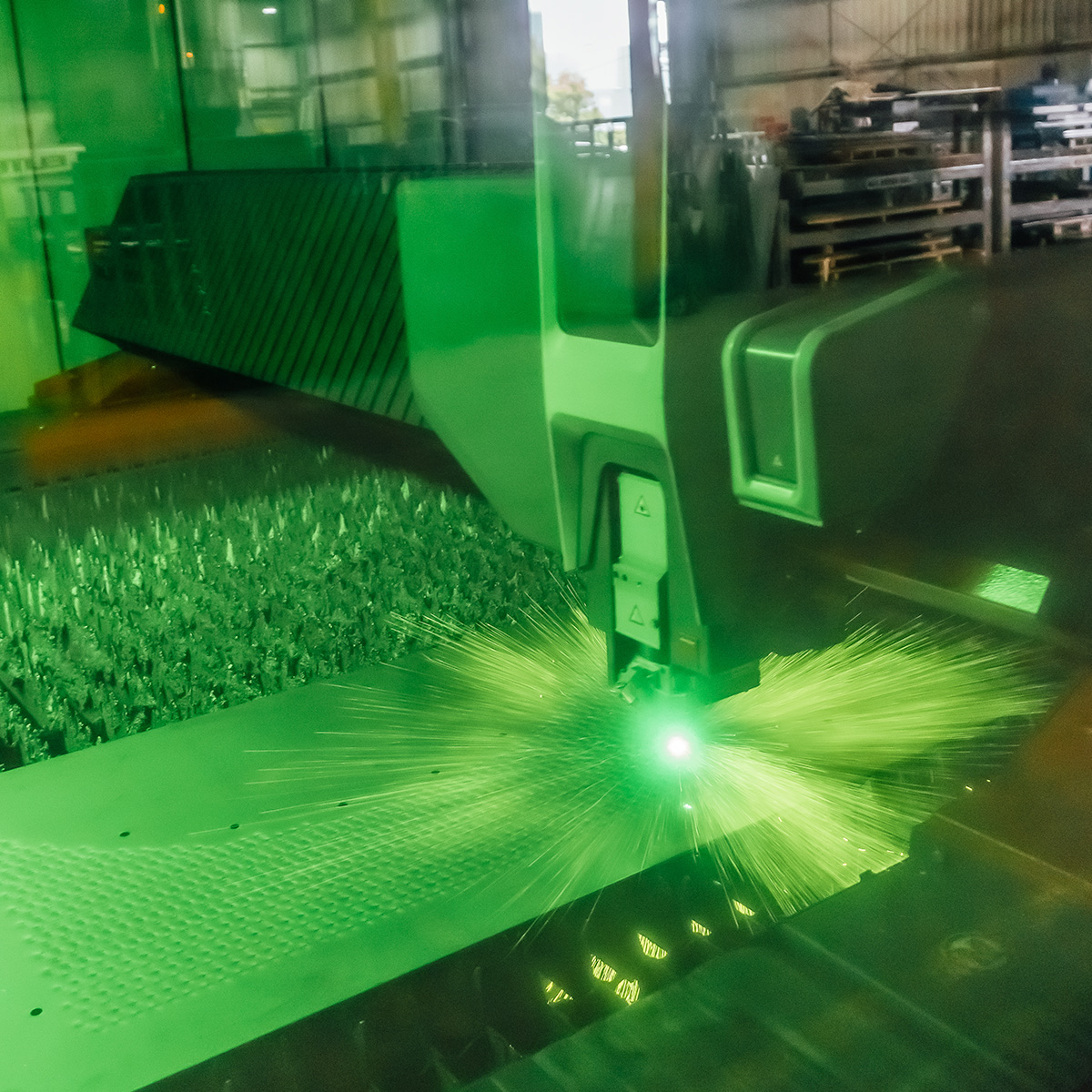

Laser cutting is a revolutionary process that burns, melts or vaporises sheet metal and other structural materials with exceptional precision, resulting in highly consistent edges.

From industrial applications to artistic masterpieces like etching, this advanced technology is being harnessed by businesses across Australia to maximise efficiency. To discover its benefits for your project, contact our team today.

Laser cutting combines precise control, powerful beam generation, and focused interaction to deliver exceptional cuts for a variety of applications. The steps involved in this thermal separation process are as follows:

- A high-power laser is generated using electrical discharges or lamps to stimulate lasing materials. The resulting coherent monochromatic light forms the laser beam.

- Beam control: Optics and computer numerical control (CNC) direct the laser beam or material. Typically, a motion control system follows a CNC or G-code pattern for cutting onto the material.

- Focusing: Mirrors or fibre optics guide the laser beam to the work area, where it is intensified through a lens. The focused beam is concentrated to a diameter that is usually under 0.0125 inches (0.32 mm), allowing for precise cutting.

- Piercing (if needed): In cases where the laser cutting process starts away from the material’s edge, a high-power pulsed laser pierces a hole in the material, so that the cutting process can begin.

- Material interaction: The laser beam interacts with the material. Depending on the desired outcome, it can burn, melt, vaporize, or be blown away by a jet of gas to create an edge.

To learn more about our laser cutting process, please do not hesitate to contact us.

At Wigley Engineering, we use a 12kw Bystronic ByStar Fibre laser. This high-precision, high-speed laser is ideal for cutting mild steel, aluminium, stainless and other metals, including copper and brass. Its 4m x 2m bed also allows us to cut larger than standard metal sheets.

We also use the ByTrans Transfer table for multiple sheets and high-volume parts. We can put a pack of common or mixed material on top, and the table will load and unload as the laser is cutting. The result? Minimal downtime and no manual lifting or handling.

Lastly, our specialists utilise the Prima Platino CO2 laser for set-up jobs, such as cutting holes and square hollow sections.

To find out more about our laser cutting technology, please contact our team.

Laser cutting is used for various applications across diverse sectors, from manufacturing and engineering processes to landscaping and auto mechanics.

If you are unsure as to whether this is the right solution for your requirements, please get in touch with our expert team today for tailored advice.

Laser cutting brings many benefits to your business, including:

Reliable consistency

Laser cutting maintains consistent precision throughout the process, as the laser beam does not wear down. This results in accurate cuts and reduces material warping, offering superior quality compared to traditional cutting methods.

Suitable for most materials

Laser cutting can handle a wide range of organic and inorganic materials, making it suitable for diverse applications across industries.

Cost and energy efficiency

With minimal risk of human error, laser processes achieve high precision with less wastage and energy consumption. That means more savings for your business.

No post-processing

Laser cutting often eliminates the need for post-processing steps, such as mechanical sealing or sanding. It can even seal the edges of textiles to prevent unravelling.

Exceptional accuracy

The resulting kerf (cut width) is incredibly narrow, closely matching the size of the laser beam. As a result, it can cut intricate geometries and shapes with extremely high accuracy. Integrated cameras can also make registration marks to automatically correct any misalignment or distortion in the original template.

Less wear and tear on your tools

Laser-cutting machines do not experience tool wear, such as dulling of tool heads. This eliminates the need for frequent tool replacements, resulting in less downtime and more savings.

Laser-cutting machines can be used on an extensive range of robust materials, including:

- Mild steel;

- Stainless steel;

- Galvanised steel;

- Aluminium;

- Zinc;

- Brass;

- Copper; and

- Other alloys, such as titanium.

The upper limit on the thickness a laser can cut depends on the material. Below, we have included the maximum thickness of the most commonly cut materials at Wigley Engineering:

- Mild Steel: up to 25mm

- Stainless Steel: up to 30mm

- Aluminium: up to 30mm

- Brass: up to 15mm

- Copper: up to 15mm

Thanks to a narrow cutting width of approximately 0.20mm and automated control, laser cutting provides outstanding dimensional accuracy to particularly high tolerances.

The length of time it takes to cut steel, aluminium or any other material depends on the laser cutting machine’s wattage and cut speed, as well as the size and thickness of the item being cut.

For a personalised estimate of your project’s timeline, please contact our experts today.

There is no one-size-fits-all cost for laser cutting metal, as prices vary according to factors such as the:

- Order volume;

- Type of raw material;

- Complexity of parts;

- Clarity of information provided by the customer; and

- Subcontractor (e.g. machining, zinc plating, powder coating or galvanising).

To receive a complimentary quote for laser cutting in Melbourne, please contact our specialists today.

Free Quote For Laser Cutting Services

To arrange laser cutting in Melbourne, please contact our team today. We will be in touch with more information as soon as possible.